Honda Accelerates Toward the Future with Solid-State Battery Production

Honda Motor Company has taken a significant step in the electric vehicle race by inaugurating a state-of-the-art demonstration line for solid-state batteries in Sakura, located in Tochigi Prefecture, Japan. This groundbreaking line, situated at Honda’s R&D center, represents a pivotal move toward the mass production of advanced batteries intended for integration into electrified vehicles in the latter half of this decade.

Spanning an impressive area of approximately 27,400 square meters, the facility is equipped with comprehensive tools to evaluate this promising battery technology. The production line features capabilities such as material mixing, electrode coating, cell formation, and module assembly. Honda plans to ramp up full-scale battery production in this facility by January 2025, while simultaneously advancing mass production efficiency and cost optimization.

A hallmark of Honda’s solid-state batteries is the innovative roll-pressing technique, which enhances the density of electrolyte layers and accelerates the production timeline. Additionally, engineers are implementing cutting-edge control technologies to curb energy consumption and minimize ancillary costs.

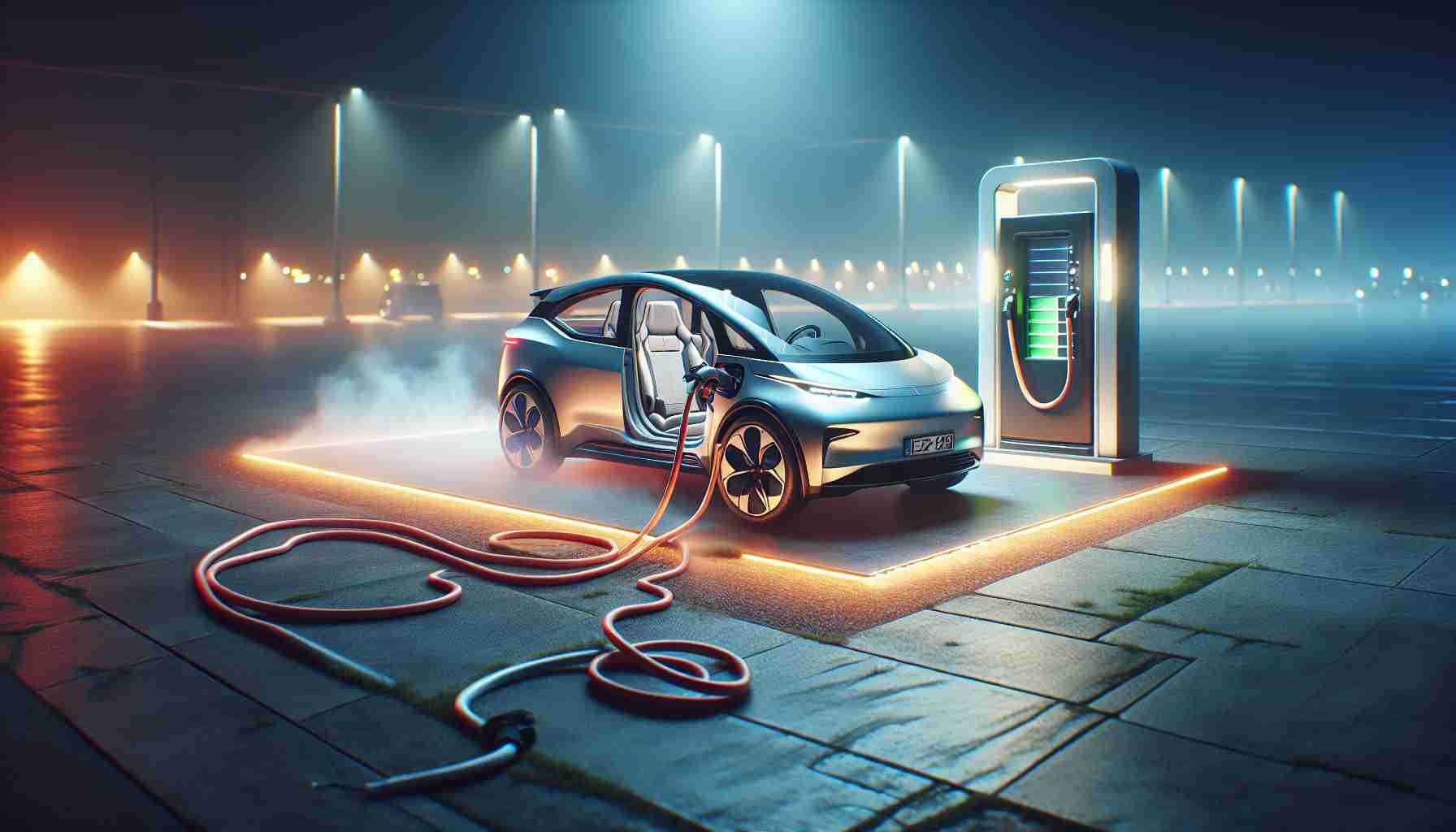

Honda envisions deploying these solid-state batteries across a diverse array of products, including cars, motorcycles, and even aircraft. By amplifying production, the company seeks to reduce costs, thereby making these powerful batteries more accessible. Honda is committed to a vision where all new vehicles by 2040 will be electric or fuel cell-powered, driven by high-energy density, heat-resistant, and fast-charging battery technologies.

Are Solid-State Batteries the Future of Energy? Discover the Untold Benefits and Potential Pitfalls

As Honda ramps up its solid-state battery production, it’s crucial to explore this groundbreaking technology and its implications for humanity and future innovations. Solid-state batteries, often hailed as the next big thing in energy storage, have garnered enormous attention for their potential to revolutionize various industries. But what are the hidden facets of this technology, and how might they shape the future?

Understanding Solid-State Batteries

Unlike conventional lithium-ion batteries, which use liquid electrolytes, solid-state batteries employ a solid electrolyte. This fundamental shift in design offers multiple advantages: increased energy density, higher safety standards, and faster charging capabilities. These benefits could see far-reaching applications not only in cars but also in consumer electronics, grid storage, and beyond.

Interesting Facts and Potential Controversies

1. Longevity and Efficiency: Solid-state batteries promise a longer lifespan and a more efficient energy cycle due to less degradation over time. However, scaling these benefits from the lab to mass production remains a significant challenge and may incur unexpected costs.

2. Heat Management: Solid electrolytes are more heat-resistant compared to their liquid counterparts, potentially reducing cooling requirements in electric vehicles. Yet, the performance of solid-state batteries under extreme weather conditions still needs thorough real-world evaluations.

3. Versatile Applications: As Honda suggests, the same solid-state battery technology can power motorcycles and possibly aircraft. Such adaptability could be a major advantage over other energy storage solutions.

4. Cost Controversies: While Honda aims for cost reduction with mass production, current production techniques are expensive, primarily due to the cost of materials and complex manufacturing processes. This raises questions about affordability for the end consumer.

Advantages and Disadvantages

Advantages:

– Safety: Solid-state batteries are less prone to leaks and explosions, offering a safer alternative to liquid-based batteries.

– Energy Density: Greater energy storage capability means potentially longer travel distances for EVs on a single charge.

– Faster Charging: Reduced charging times could make electric vehicles more appealing to consumers used to quick refueling.

Disadvantages:

– High Initial Costs: Despite potential for cost reduction, initial investments in production infrastructure are significant.

– Manufacturing Complexity: Developing scalable manufacturing techniques remains a technological hurdle.

– Material Availability: Dependence on materials that are not readily available could limit wide-scale adoption.

The Road Ahead: Queries and Considerations

– Is scalability a realistic goal? Honda’s plans mark a critical step, but can the industry globally replicate such developments on a large scale quickly?

– How will consumer perceptions change? As technology evolves, will the public embrace these novel batteries, and how might this shift affect other battery types?

Related Links:

– For more on emerging battery technologies, visit Tesla

– To learn about battery research and development, explore Panasonic

As solid-state battery development progresses, its future implications for society and technology unfold. With Honda leading the charge, these developments bring both exciting opportunities and formidable challenges that could redefine energy utilization and technological innovation in the coming decades.