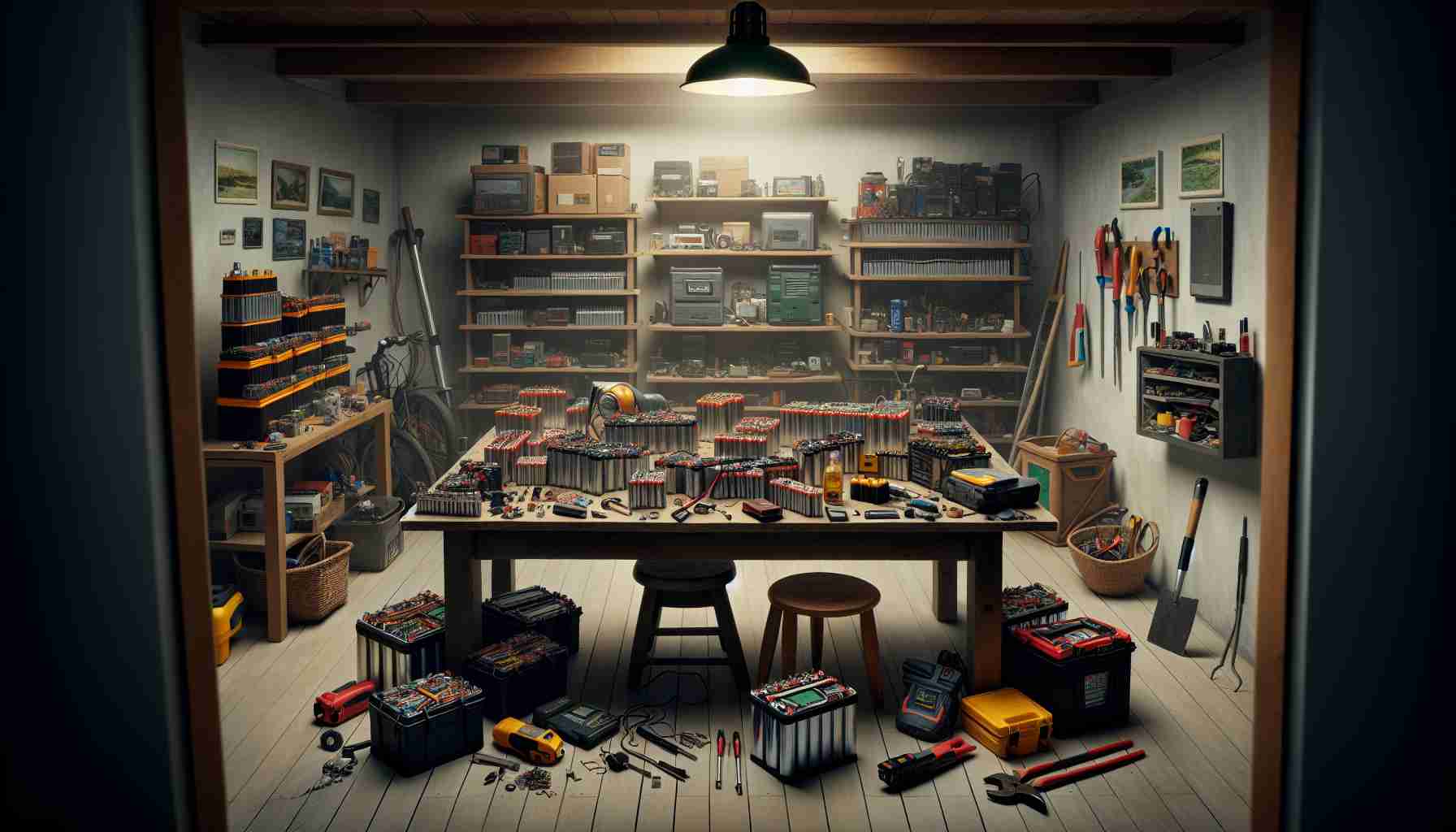

In recent years, Dharmawan Kusna Handoyo has transformed his passion for building DIY battery packs into a thriving business. Working diligently in his small cubicle, he meticulously solders batteries to create e-bike battery packs that offer longer range and improved capacity. Handoyo’s success is part of a growing trend in Indonesia, where the booming e-bike market and the absence of battery regulations have created opportunities for battery packers like him.

The rise of electric two-wheelers, known as E2Ws, in Indonesia can be attributed to a government subsidy introduced in 2023. With financial incentives in place, the number of registered e-bikes skyrocketed, nearly tripling in just a year. However, the lack of regulations surrounding batteries has given rise to a market for homemade and inexpensive replacement batteries. Local Facebook forums and popular e-commerce platforms are flooded with advertisements for locally made batteries, enticing riders with their competitive prices and extended range.

One e-bike rider, Hadi Wijaya, replaced his original battery with a homemade one made by a friend. Not only was the homemade battery cheaper, but it also offered a longer range of up to 150 kilometers on a single charge, compared to the original battery’s 100 kilometers. Wijaya’s experience is not unique, as many other e-bike users have opted for homemade batteries over branded ones.

While the homemade batteries may seem like a cost-effective solution, concerns regarding safety and reliability arise due to the absence of regulation. Battery packers source cylindrical lithium-ion cells from various suppliers and manually assemble them into packs using nickel strips. The lack of standardized regulations means that variations in cell discharge rates and capacity can lead to unexpected problems such as battery damage or sudden shut-offs.

Additionally, the e-bike industry’s lack of standardized battery sizes and designs further complicates the issue. Each e-bike manufacturer has its own specifications, resulting in more than 20 different battery sizes in the market. This discrepancy makes it challenging for consumers and battery packers alike to find certified batteries that fit their specific e-bike model.

In an attempt to address these concerns and standardize EV batteries, the Indonesia Battery Corporation, supported by state companies and partnering with Hyundai and LG, plans to launch its own battery-swap technology using the country’s abundant nickel reserves. However, the thriving market for homemade batteries poses a threat to such initiatives. The increasing number of homemade battery producers drives up the demand for used battery cells, sometimes obtained from scrapped or stolen branded batteries, further exacerbating safety risks.

To ensure the safety and reliability of e-bike batteries, stakeholders agree that proper safety procedures and regulations need to be established. Without careful attention to design, packing, and testing, accidents may occur. As Indonesia strives to develop a sustainable and standardized battery industry, addressing the concerns surrounding homemade batteries becomes paramount for the future of the burgeoning e-bike market.

The e-bike market in Indonesia has experienced significant growth in recent years, fueled by government subsidies and financial incentives. However, the lack of regulations surrounding batteries has led to the emergence of a market for homemade and inexpensive replacement batteries. This trend has both positive and negative implications.

On the positive side, homemade batteries offer a cost-effective solution for e-bike users, with competitive prices and extended ranges. Many consumers have opted for these batteries due to their affordability and performance advantages. For example, Hadi Wijaya replaced his original e-bike battery with a homemade one made by a friend, which offered a longer range compared to the original battery.

However, concerns regarding safety and reliability arise due to the absence of regulations. Homemade battery packers source lithium-ion cells from various suppliers and manually assemble them into packs, which can lead to variations in cell discharge rates and capacity. This lack of standardization can result in unexpected problems such as battery damage or sudden shut-offs.

Another challenge is the lack of standardized battery sizes and designs in the e-bike industry. Each manufacturer has its own specifications, leading to more than 20 different battery sizes in the market. This discrepancy makes it difficult for consumers and battery packers to find certified batteries that fit their specific e-bike model.

To address these concerns and standardize EV batteries, the Indonesia Battery Corporation, supported by state companies and partnering with Hyundai and LG, plans to launch its own battery-swap technology. This initiative aims to utilize the country’s abundant nickel reserves and establish a more sustainable and standardized battery industry. However, the thriving market for homemade batteries poses a threat to these initiatives, as it increases the demand for used battery cells, sometimes obtained from scrapped or stolen branded batteries.

In conclusion, while homemade batteries offer cost-effective solutions and improved performance, concerns regarding safety, reliability, and standardization are prominent. Proper safety procedures and regulations need to be established to ensure the safety and reliable operation of e-bike batteries. As Indonesia works towards developing a sustainable and standardized battery industry, addressing the issues related to homemade batteries becomes crucial for the future of the e-bike market.

For more information on the e-bike market in Indonesia and related industry insights, you can visit Indonesian Industry.