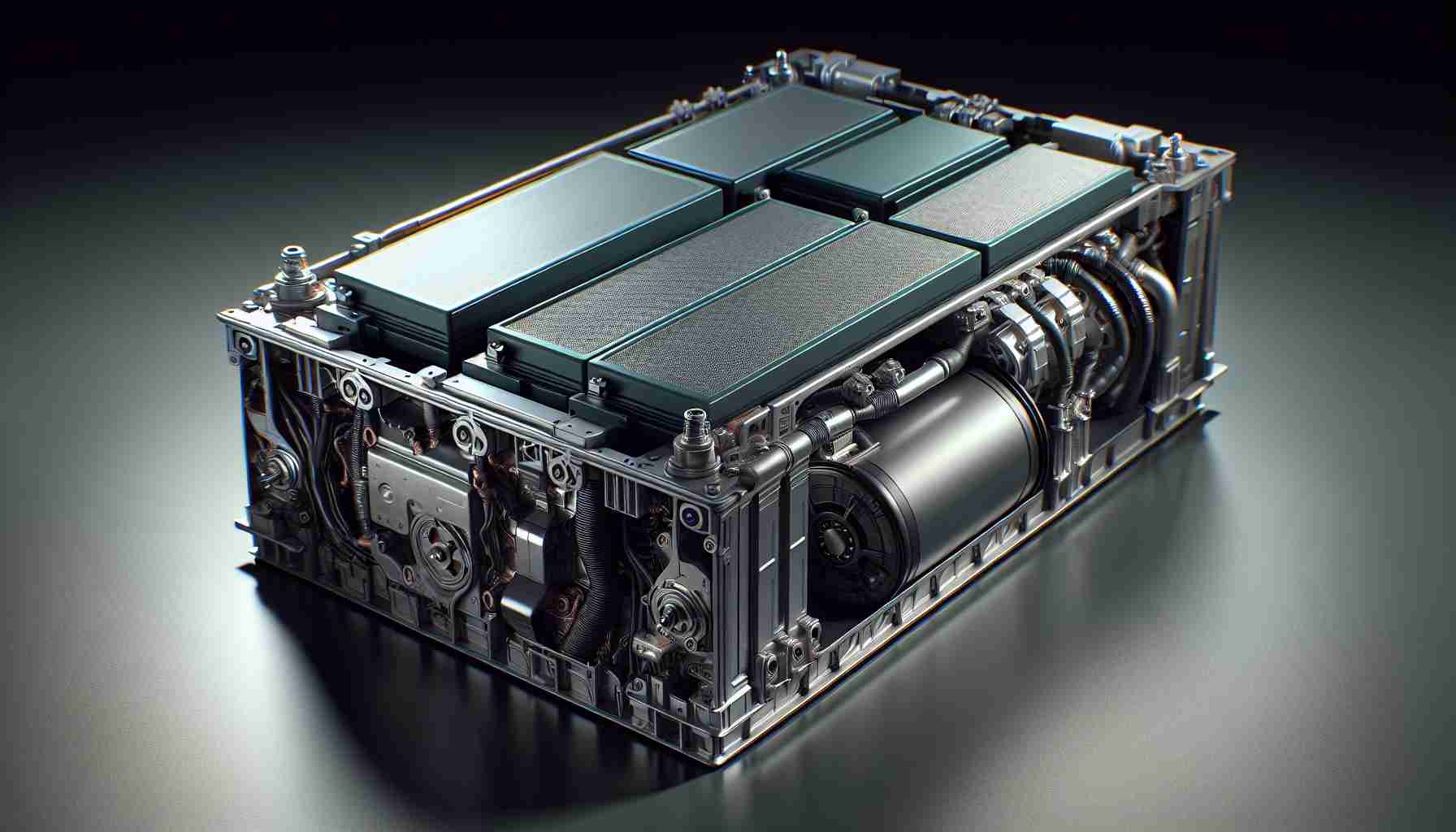

In the rapidly evolving world of battery technology, ensuring high-quality production is paramount to maintaining safety and performance. Batteries are intricate components, and any minor defect during manufacturing can lead to significant issues, including recalls and safety hazards. As a solution, battery manufacturers are implementing rigorous quality control measures. Automated Defect Recognition (ADR) systems are becoming essential tools, enabling swift inspections and minimizing the time dedication required from human inspectors.

The shift toward electrification is driving a monumental change in energy consumption, and with it, a surge in demand for batteries. Recent statistics reveal a staggering investment of $195 billion in battery production for 2022 and 2023. With global battery storage capacity significantly increasing, manufacturers face the challenge of scaling production while maintaining high standards of quality and efficiency.

Non-destructive testing (NDT) technologies such as X-ray and computed tomography (CT) play a crucial role in this context. These advanced inspection methods allow for an in-depth analysis of battery components without causing damage. By detecting defects such as misalignments and structural issues early on, manufacturers can enhance reliability and reduce waste.

Moreover, the integration of artificial intelligence (AI) into inspection processes promises to further streamline operations. AI can assist in automating assessments, thereby allowing experts to focus on interpreting critical results. This synergy between technology and human oversight will be pivotal in the journey toward producing safer and more efficient batteries for the future.

The Impact of Advanced Battery Technologies on Lives and Communities

As the world transitions toward renewable energy sources and electrification, the role of battery technology is becoming increasingly critical in shaping the lives of individuals, communities, and entire nations. This transformation is not merely a technical revolution but also a societal one that carries implications for environmental sustainability, economic growth, and energy independence.

The demand for batteries is projected to soar exponentially as electric vehicles (EVs) gain popularity, and solar and wind energy become prevalent. This surge in demand is not without its challenges; it raises questions about sourcing raw materials like lithium, cobalt, and nickel, which are often extracted in regions facing ethical issues. Countries like the Democratic Republic of the Congo, where a significant amount of cobalt is sourced, are grappling with human rights controversies and environmental concerns related to mining practices.

Moreover, the rise of battery production is spearheading economic opportunities in various regions. According to estimates, the battery market is expected to create around 400,000 jobs globally by 2030. Communities that invest in battery manufacturing and research facilities can experience revitalized economies. For instance, states like Michigan in the U.S. are witnessing growth in the auto industry, not just through traditional car manufacturing but increasingly through the production of electric vehicles and their components, including batteries.

However, there are also notable controversies surrounding battery technology. The environmental toll of mining lithium and other minerals is significant; it can lead to water shortages and pollution in local ecosystems. The debate over the sustainability of battery production is fierce, with advocates pushing for more eco-friendly mining practices and the development of recycling technologies. As society becomes more aware of the implications of battery production, pressure is mounting on manufacturers to adopt ethical sourcing practices and invest in sustainable technologies that minimize environmental degradation.

On the consumer level, the advent of advanced battery technology has transformative effects on daily life. From the convenience of electric scooters and bikes to the widespread adoption of EVs, the shift toward electrification is making transportation cleaner and more accessible. Statistics show that in many urban areas, more than 50% of new vehicle sales are electric, with expectations for this number to rise significantly in the coming years. As a direct result, air quality is expected to improve in densely populated cities, potentially reducing health issues related to pollution.

The integration of technologies like Artificial Intelligence (AI) and advanced inspection methods like X-ray and computed tomography (CT) into battery manufacturing promises to further enhance safety and reliability. Investment in these technologies ensures that batteries produced are of the highest quality, reducing the risk of accidents and product recalls. This focus on quality not only reassures consumers but also solidifies the reputation of manufacturers in a competitive market.

In conclusion, the evolution of battery technology is not just a technical change; it is fundamentally impacting lives, transforming communities, and influencing the economic landscape of entire countries. The future will likely see continued advancements as the global community strives for greener, more efficient energy solutions. As challenges arise, the responsibility falls on consumers, corporations, and governments to advocate for sustainable practices in the battery industry. More information on this growing field can be found at IEEE.

The article has been updated: 2024-11-05 15:00

Here are some suggested related links to include in your post titled “The Future of Battery Manufacturing: Ensuring Quality through Innovation”:

1. Battery University – A comprehensive resource for battery technology, offering insights into manufacturing processes, innovations, and quality assurance methods.

2. Batteries International – A leading publication focused on the battery industry, featuring articles on technological advancements and market trends.

3. IDTechEx – Provides market research and analysis on emerging technologies in battery manufacturing and developments in energy storage systems.

4. ResearchGate – A network where researchers publish their findings, including studies on new battery technologies and innovations in manufacturing quality.

5. Energy Storage Journal – Covers the latest news and research in energy storage technology, including battery innovations and their implications for manufacturing.

6. ScienceDirect – An extensive database of scientific articles and journals, offering in-depth research papers on battery manufacturing techniques and quality assessment.

7. Green Car Congress – Focuses on advanced transportation technologies, including news on battery innovations and their manufacturing processes.

8. U.S. Department of Energy – A government site that provides information and resources related to energy technology, including initiatives to improve battery manufacturing quality and efficiency.

9. Tesla – A prominent player in battery manufacturing and electric vehicles, their site offers insights into innovative manufacturing processes and sustainability practices.

10. Automotive World – Provides analysis and reporting on the automotive industry, including the latest developments in battery technology and manufacturing standards.

These links will enhance your post by providing readers with additional resources and perspectives on battery manufacturing and innovation.

The article has been updated: 2024-11-06 01:56

What are some innovative technologies being introduced in battery manufacturing to ensure quality?

One of the most promising innovations in battery manufacturing is the integration of advanced automation and robotics, which enhances precision and consistency in the production process. Additionally, the use of artificial intelligence (AI) and machine learning can help monitor quality in real time, allowing for immediate adjustments to optimize battery performance and reduce defects. Further, the development of new materials, such as solid-state electrolytes, is not only improving energy density but also enhancing safety and longevity, which are critical for high-quality batteries. Finally, improved recycling techniques are being implemented to ensure that materials are reused efficiently, thereby maintaining quality standards while being environmentally sustainable.